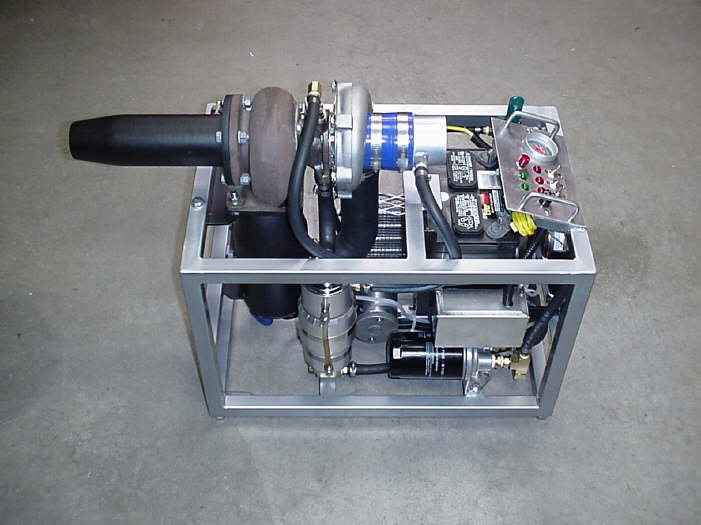

Revolutionizing Jet Propulsion With

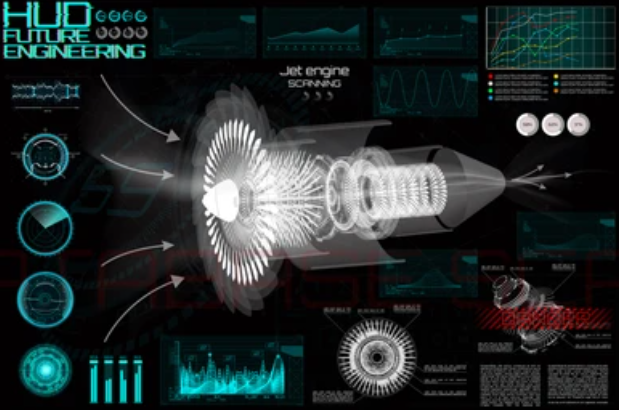

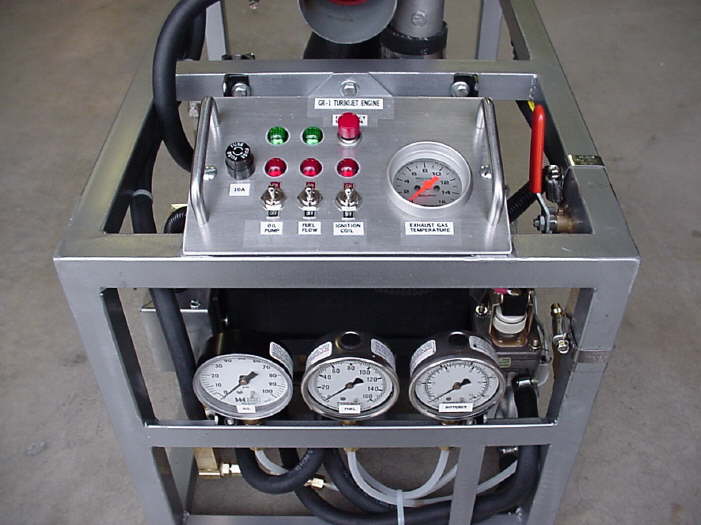

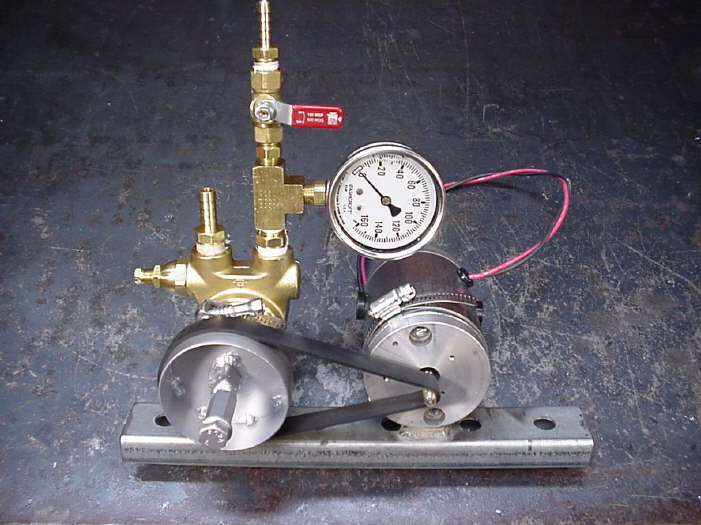

Experience the next generation of turbocharger jet engine technology—engineered for maximum efficiency, responsive control, and raw power. Designed for aerospace enthusiasts, students, and future-forward developers.

%

Functional

+

Testing Hours Logged